San Antonio, TX, USA, 6 June 2016

Trajan Scientific and Medical (Trajan) announces two advancements in the development of devices and components for nano-electrospray ionization mass spectrometry (nanoESI-MS), in collaboration with the University of Adelaide in Australia, and with Queen’s University and Université Laval in Canada.

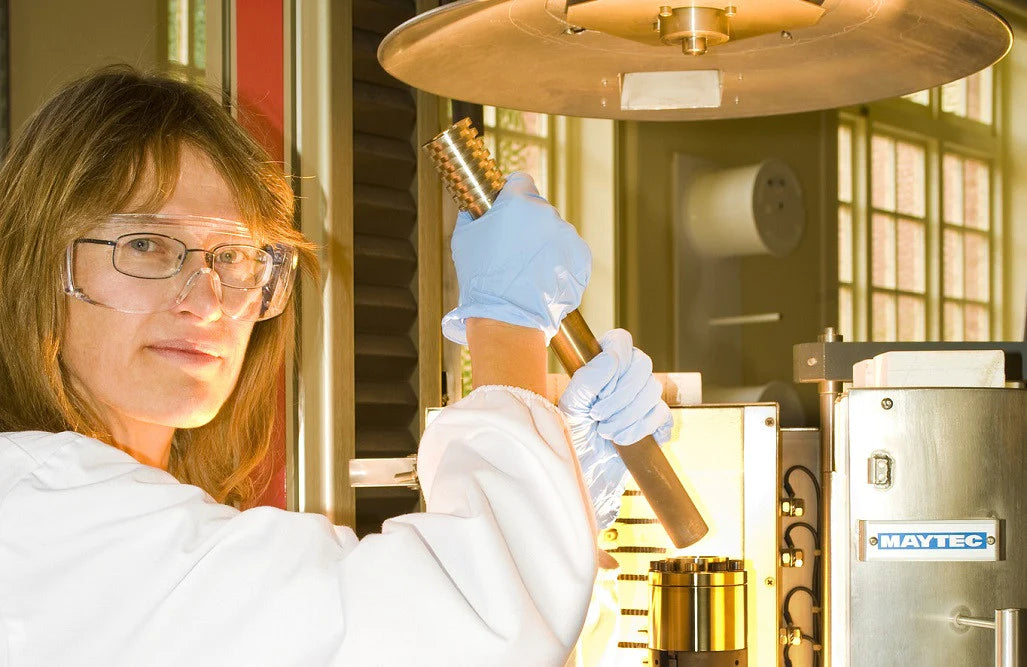

Trajan and the University of Adelaide’s Institute for Photonics and Advanced Sensing (IPAS) have been awarded an A$0.5 million Australian Research Council (ARC) Linkage grant to create glass capillaries and tubes with advanced geometries to enhance the sensitivity of mass spectrometry.

While photonics has a long history of developing unique glasses for optical sensors, there has only been an embryonic investigation into adopting these glass fabrication processes for mass spectrometry.

By collaborating on new R&D projects, Trajan can take full advantage of its recent expansion of glass fabrication capabilities, now comprising advanced manufacturing facilities in Melbourne, Australia, as well as San Diego, USA, and its co-location within IPAS in Adelaide, Australia.

Significant enhancement of nanoESI-MS sensitivity in this fabrication work with IPAS is expected to accelerate progress in disease research, biomarker discovery and drug development.

Trajan and Queen’s University (Queen’s), Kingston, Canada, via PARTEQ Innovations, the University’s technology transfer organization, have established a framework to license Professor Richard Oleschuk group’s multi-lumen emitter tip technology developed in collaboration with Professor Younès Messaddeq of Université Laval’s Center for Optics, Photonics and Lasers (COPL), Québec City, Canada.

Queen’s, Université Laval and Trajan will collaborate to commercialize multi-lumen emitter tip technology and also undertake further research to develop the next generation of emitter tips for the mass spectrometry industry.

Mr Mike Bailey, General Manager of Trajan’s Precision Fluidic Solutions Business Unit said he was encouraged by the speed at which Trajan and its University partners have been able to execute on the evolution of the glass fabrication capabilities from photonics to the field of mass spectrometry.

“In less than nine months Trajan has moved from a hypothetical discussion with our academic partners to execute our first tangible collaboration in the development of a next generation of glass devices and components to enhance the sensitivity of electrospray mass spectrometry. We are now keen to see that enthusiasm translate into new products that benefit the mass spectrometry community” said Mr Bailey.

Prof. Richard Oleschuk said this is an example of the interesting things that can happen when you have people with expertise in separate fields work with one another, and each have access to cutting edge fabrication and instrumentation resources. It is gratifying to see an idea become both a research reality and great opportunity with a supportive commercial partner.”

Prof. Younès Messaddeq, head of the Canada Excellence Research Chair in Photonic Innovations at Université Laval, said that it is the remarkable synergy between the research teams at Queen’s University and Université Laval that has allowed the development of this novel technology over such a short period of time.

Download

Press Release [PDF]

More Information

- Trajan Scientific and Medical www.trajanscimed.com

- University of Adelaide’s Institute for Photonics and Advanced Sensing www.adelaide.edu.au/ipas

- Queen’s University at Kingston www.queensu.ca

- Queen’s University Department of Chemistry www.chem.queensu.ca

- Prof. Richard Oleschuk www.faculty.chem.queensu.ca/people/faculty/oleschuk

- PARTEQ Innovations www.parteqinnovations.com

- Université Laval www.ulaval.ca

- Université Laval’s Center for Optics, Photonics and Lasers www.copl.ulaval.ca

- Prof. Younès Messaddeq www.cercp.ca

Media Contact Information

Trajan Scientific and Medical

media@trajanscimed.com

44 (0) 1244 403 100

Photo courtesy of the University of Adelaide: IPAS Researcher Heike Ebendorff-Heidepriem loading a specially modified extrusion furnace.